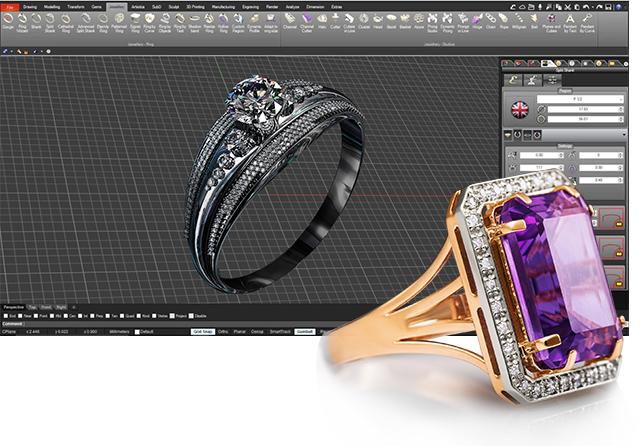

The advances in software and the ease of use each of the differing types of CAD packages allow for, now provide a revolutionary role within the traditional bench jewellers creation of one-off pieces.

With CAD software, a jeweller can now see exactly what their designs will look like before they even put saw to metal. This advantage also acts as a great selling point with your customers. Showing the buyer exactly what they are paying for is a powerful tool that can help to seal the deal.

Complex designs are sketched up using commands that may seem very alien for the beginner but are soon mastered with daily practice. I regard it like learning a new trade from scratch except the advantage is to the current bench jeweller that knows what parameters are needed to hold a stone incorrectly. How much metal it takes to keep a stone safe is not something you learn overnight so the advantage like I said goes to those that have worked in the trade.

Although the software does not come cheap even in comparison to an office suite from Microsoft or adobe photoshop, the amount of time and money you can save by migrating to CAD, in the long run, is phenomenal. For instance, if you have to make a brand new custom made head for a particular stone, there is generally a lot of waste after filing and sawing but if you use the CAD with CAM (computer-aided manufacturing) all you have to do is saw off the spru and clean up the cast when it is returned from the casting company. Within the software is the ability to calculate the weight of what the design would turn out like in whatever metal is required giving the added ability to price the piece almost exactly.

Another advantage is taking your workbench anywhere. Your laptop is the new workbench for the digital jeweller and working at home is something to get used to. However, staring at a screen might not seem to be the ideal job to some and can even be seen as cheating to other jewellers that prefer to use the traditional methods the whole time. Personally, I believe that progress can be made using new tools and the use of CAD by jewellers is simply a new tool in the toolbox.

If a sharper blade was found, there would be no complaints or a longer-lasting file due to new nanotechnology, that too would be welcomed. Then what may I ask is wrong with speeding up a process normally done by hand by using newer and smarter technology?

My final word is this, small Jewellers that want to compete with larger jewellers can now level the playing field by using this system. You don’t need to stock thousands of Euro worth of precious inventory, it can all be stored and created virtually on a computer, ready to show on screen to any potential customer looking for something unique and different.